Recent results of RFCS DEPREX research project – Early detection and prevention ot tuyere damaging conditions for extension of tuyere life time at blast furnaces

Registration for Webinar

|

|

joerg.adam@bfi.de hauke.bartusch@bfi.de

The organisers of the webinar will declare guidelines on adherence to competition-law regulation and will take care of their compliance.

DEPREX project abstract

Up to now the damage of a blast furnace tuyere is an unpredictable incident during usual blast furnace operation, which happens in average between 30 to 120 times a year. Each single tuyere damage effect a stoppage of the whole blast furnace of several hours for repair. Those unplanned stoppages caused by tuyere damage effect:

- additional consumption of energy (coke, auxiliary energy, etc.),

- additional costs mainly for coke, staff and equipment,

- increased risks for severe operational incidents and occupational health

- additional emissions (CO2) and

- loss of production.

Although BF operators and R&D institutes have done a lot of effort analysing the tuyere damages and trying to find the reasons for those incidents there are still major gaps what to do or avoid for lowering tuyere damage incidents at BF operation. The main difficulty up to now was the “singular” character of the incidents due to local thermal overload and the massive destruction effect within short time, which has led to an acceptance of those damages as usual in the past. Consequently, no operational tools are available, yet, to solve the problem.

The RFCS DEPREX research project aims to develop an operational online control system for early detection and prevention of tuyere damaging conditions in order to decrease the frequency of unplanned BF stoppages for significant reduction of energy consumption and costs in BF operation.

DEPREX objectives

The damage of a blast furnace tuyere is an unpredictable incident in blast furnace operation. Each single tuyere damage effect a stoppage of the whole blast furnace of about two hours up to eight hours for repair. Although, the hot blast is stopped and no hot metal is produced, coke is consumed and additional coke has to be charged. Energy is spent without any benefit.

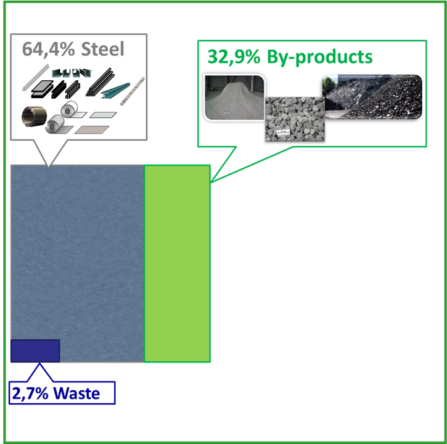

The additional energy caused by a BF stoppage due to tuyere damage has been estimated roughly to about 1.600 TJ each year for German BF only. The estimation implied a damage frequency of 45 damages per blast furnace and year. Assuming the same tuyere damage frequency for blast furnaces in EU 28 the useless energy consumption results of more than 6.000 TJ. Doubling the extension of BF tuyere life time gives a benefit of 3000 TJ. Therefore reduction of tuyere damage frequency is an important aim to the sustainable energy use and reduction of costs strengthening the competitiveness of the European iron and steel industry.

The aim of the planned RFCS project is the development of an online BF tuyere damage risk assessment system for early detection and prevention of tuyere damaging conditions in order to decrease the frequency of unplanned BF stoppages. The decreasing number of unplanned blast furnace stoppages due to tuyere damages enables a significant reduction of energy consumption and costs in blast furnace operation. Furthermore, it decreases the risk for the occupational health due to e. g. contact of blast furnace staff with toxic CO containing gas and hot metal during exchange of damaged tuyeres. Therefore, each prevented tuyere damage helps to increase safety of BF staff.

Consequently, the proposed project contributes to the RFCS programme objectives (Council Decision 2008/376/EC).

DEPREX research approach

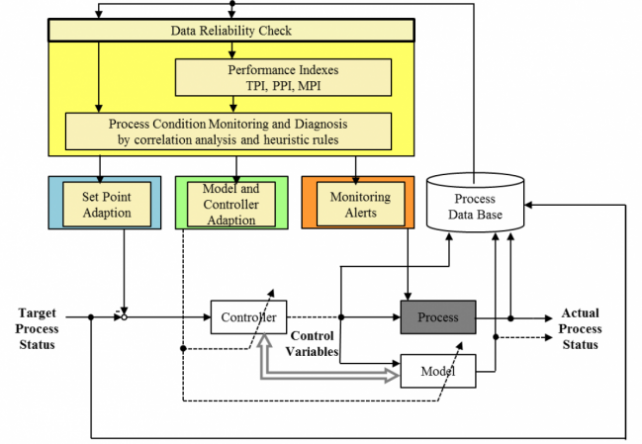

To reduce the frequency of unplanned stoppages due to tuyere damages an innovative BF tuyere damage protection approach is developed with the project DEPREX. The key idea of this new approach is to detect early indications for BF tuyere damaging conditions before the tuyere damaging process has started and to prevent those conditions with suitable countermeasures in BF operation. Thus, the BF tuyere life time will be extended. The new integrated DEPREX approach is shown schematically in the figure below.

Additional knowledge about BF tuyere damage mechanism and weak spots / areas at tuyeres is generated by advanced analysis of the degradation of BF tuyere material properties over the life time of such components. Up to now metallurgical and thermo chemical investigations have only been carried out at damaged tuyeres. The chronology of material properties of BF tuyeres “from cradle to grave” has never been investigated before and is expected to give important additional information. The additional knowledge about tuyere damaging mechanisms is one key component in the development of the new online BF tuyere damage risk assessment system.

In order to get the necessary thermal data from the BF tuyere area new operational BF measuring tuyeres (MT) with advanced fibre optical temperature measurement device will be developed. The BF measuring tuyeres with fibre optical temperature measurement, generates important information concerning the thermal conditions in the BF hearth for the BF tuyere damage risk assessment system.

The new operational BF tuyere optical monitoring system (OMS) is used for monitoring of the BF tuyere and detection of tuyere damaging conditions. The system generates additional input for the new BF tuyere damage protection system. The new technology can be used as trigger for countermeasures at an early stage. Consequently, the advanced optical monitoring system brings an added value to the early detection of abnormal tuyere operation conditions effecting tuyere damages.

This video can only be viewed with Chrome or Opera.

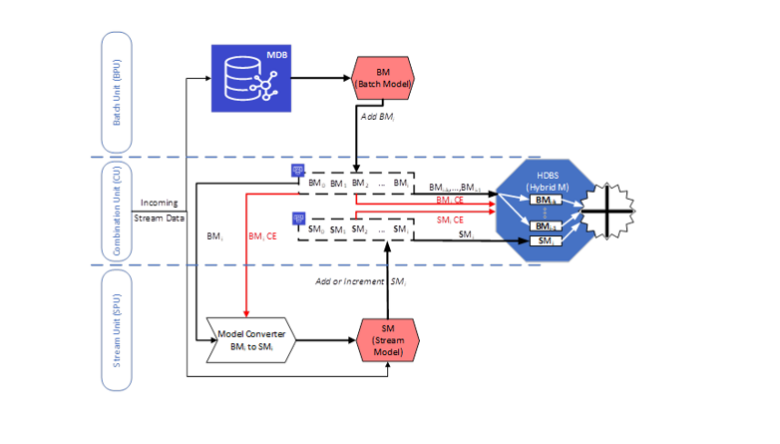

The data and information generated with the new operational BF tuyere monitoring systems (MT & OMS) together with operational data of the blast furnace are concluded, analysed and processed in the model-based online tuyere damage risk assessment system. The aim is an early detection and prevention of BF tuyere damaging conditions with appropriate counteractions of the BF operators.

The basic idea of this new online BF tuyere damage risk assessment system is, first, to provide new operational BF tuyere monitoring systems improving and combing the prototype measuring tuyeres and the tuyere optical control system established in a previous project. Second, the measuring data will be correlated with operational data of the blast furnace. The results will be exploited for industrial online application in a model based online BF tuyere damage risk assessment system. The new BF tuyere damage protection system is composed of the following modules/ components:

- New operational BF measuring tuyeres with advanced fibre optical temperature measurement at the whole tuyere surface extending into the raceway

- New operational BF tuyere optical control system with advanced extraction of parameters representing conditions in and in front of the tuyere

- Online monitoring system for early recognition of tuyere damage risk combining statistical and model based analysis of operational BF and measuring tuyere data

- New process control strategies for different escalation levels of tuyere damage risk

The overall aim of the DEPREX RFCS research project is the early detection and prevention of tuyere damaging conditions for the extension of BF tuyere life time. The decrease of the frequency of unplanned blast furnace stoppages due to tuyere damages effect a significant reduction of energy consumption and costs in blast furnace operation, contributing to the RFCS programme objectives and strengthening the competition of ironmaking in Europe.

| VDEH-Betriebsforschungsinsitut GmbH |   |

| thyssenkrupp Steel Europe AG |  |

| voestalpine Stahl GmbH | |

| ISD Dunaferr Co. Ltd |  |

| Furol Co. Ltd |  |

| The project leading to this application has received funding from the Research Fund for Coal and Steel under grant agreement No 709424. |  |

Über den Autor