RealTimeCastSupport project abstract

Thermal and fluid-mechanical conditions in continuous casting moulds are only roughly known although highly relevant for the product quality. Manual process control is difficult due to the great number of influencing factors. Therefore, the aim of the research is the digitalisation and optimised control of continuous casting machines. Large data streams will considered online and assist the caster operators with a real-time support system. This system will provide suggestions for an optimised process control in real-time. It will be developed with application of new measuring techniques and representation of the casting machine by a digital twin.

The kick-off-meeting for the RFCS project “Embedded real-time analysis of continuous casting for machine-supported quality optimisation” (RealTimeCastSupport) took place on 1st and 2nd of October 2019 at premises of the coordinator BFI.

| VDEh-Betriebsforschungsinstitut GmbH |

|

| AG der Dillinger Hüttenwerke |

|

| voestalpine Stahl GmbH |

|

| Materials Processing Institute (MPI) |

|

| Minkon SP ZOO |

|

RealTimeCastSupport objectives

The main objective of the proposed research project is:

- Improved product quality in terms of reduction of hard spots on heavy plates and slivers on cold-rolled strips.

The main objective is accompanied by several sub-objectives which can be assigned to the already mentioned main components of the research project:

Online monitoring of tundish and mould with implementation of new measuring techniques

- Simultaneous temperature measurements at different positions in the tundish as well as in the mould and monitoring of the casting powder coverage.

- Online application of new measurement technologies FOTS and DynTemp® for temporally high resolving temperature.

- Implementation of IR-based 2D casting powder monitoring.

Exploitation of various CC data and surface inspection to predict reliability of steel production

- Offline material tracking, synchronisation of data streams and statistical analysis by application of big data technologies.

- Identification of defect promoting scenarios by correlation of casting powder monitoring, statistical results and hard spot as well as sliver detection.

- Realisation of an offline 3D digital twin of the CC tundish and mould considering transient steel melt flow including turbulence, filling level changes, heat transfer, inert gas feeding and solidification.

- Offline reproduction of the identified defect promoting scenarios with the 3D digital twin in order to find thermal and fluid mechanical reasons for the detected behaviour.

Advanced CC process control in real-time offering machine supported decisions

- Development of countermeasures against the defect promoting scenarios aiming at the adjustment of the thermal and fluid-mechanical caster status in order to strengthen the options for real-time process control. Assessment of their potential with the digital twin.

- Adjustment of operational windows for continuous caster operation aiming at an advanced process control.

- Development and testing of new mould powders and intumescent coatings aiming at modification and improved control of heat transfer in the mould.

- Modification of electromagnetic actuator’s operation mode.

- Offline identification of rules for the operation of the casting machine based on conclusions from measurements, statistical analysis and application of the 3D digital twin.

- Online application of a real-time support system with implementation of the defined rules.

- Online implementation of advanced real-time CC process considering large data streams.

- Verification of the effectivity of real-time support system during operational application.

RealTimeCastSupport research approach

Online monitoring of tundish and mould with implementation of new measuring techniques

|

Available measurement techniques |

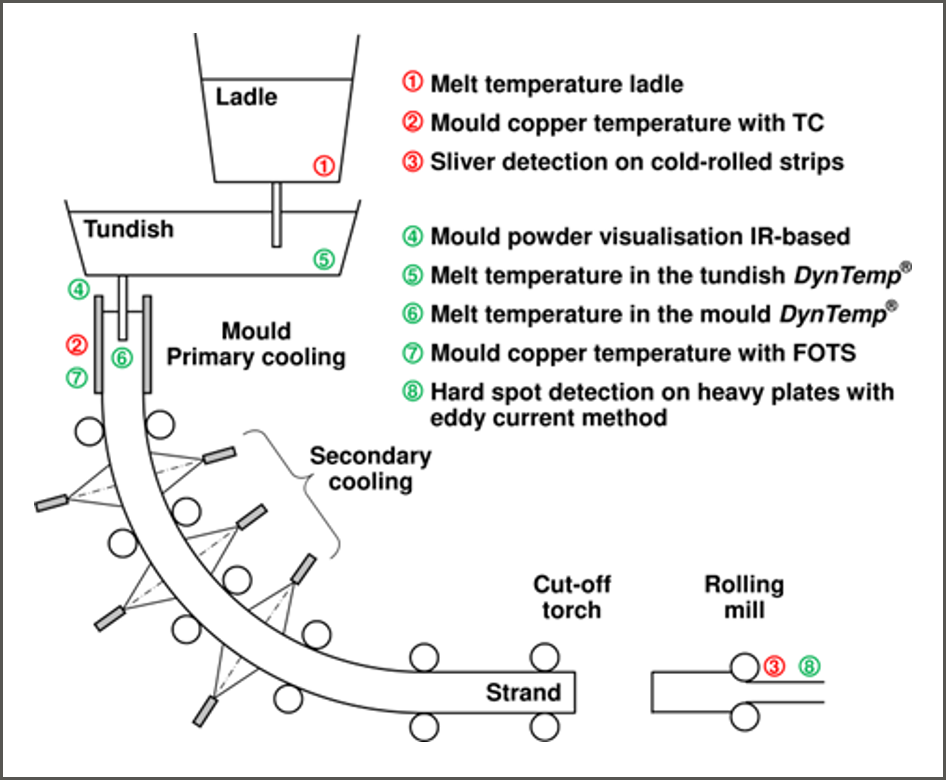

An important research approach of this project is the simultaneous temperature measurements at different positions in tundish as well as in the mould and the monitoring of the casting powder coverage. This will provide a deeper insight of the conditions in the casting machine depending on time, i.e. transient conditions like ladle or tundish changes can be analysed in detail. The results can then be connected to quality information, i.e. hard spots appearance on heavy plates as well as sliver appearance on cold-rolled strips. The online application of the new measurement technologies FOTS and DynTemp® for temporally high resolving temperature is scheduled as well as the implementation of IR-based 2D casting powder monitoring system. The figure below illustrates the availability and position of the utilised measuring techniques.

Additionally, already available measurements, analysis and online modelling results systems will be utilised for the real-time machine support system:

- Melt temperature in the ladle.

- Temperature in the copper mould plates measured with thermocouples.

- Sliver detection on the cold-rolled strips.

Exploitation of various CC data and surface inspection to predict reliability of steel production

A self-evident element of this project component is the material tracking and the synchronisation of the available data streams. It has to be ensured that the quality information, i.e. hard spots and sliver occurrence, can be assigned to the corresponding casting conditions. But the casting conditions are not only valid for a certain time. They were taken at different positions, i.e. measurements with regard to the determined product quality have to be taken at different times, e.g. melt temperature in the tundish and in the mould, casting powder cover and copper plate temperatures. They have to be synchronised knowing well that different techniques show different idleness, e.g. temperature measurements in the copper plates react slower on melt temperature changes than the DynTemp® measurements. Material tracking algorithms are already available at the steel plants of the industrial partners. They will be used in the frame of the research project. Synchronisation of the measured data will be worked out in the frame of the comprehensive statistical analysis.

For the analysis and assessment of the mentioned data different methods from Data Mining and Big Data analytics will be used. For the computations with the 3D digital twin the analysis of influencing factors of casting is necessary in order to find the target parameter, e.g. the occurrence of hard spots. Therefore, a common analysis of the casting parameters, i.e. the various temperature measurements in tundish and mould and the results of image processing, will be executed by means of Data Mining methods in a first step. Several methods like Decision Tree analysis, artificial neural networks, e.g. Self Organising Map or Deep Learning methods, and others will be applied to detect relationships between the input parameters and the target one. The aim is to identify those inputs – or derived features- which are influencing mainly the target parameter. By the derived subset of input values a digital twin of the casting machine, i.e. a transient CFD model of the considered casting machine, will be developed in order to estimate the impact of altered parameters on product quality features. The findings will be integrated in the real-time support system by the definition of a set of rules describing possible countermeasures. The real-time support system will provide information about possible critical process conditions causing defects and will support operators to find appropriate countermeasures, i.e. it supports the decision making.

Based on these findings measures for an improved thermal and fluid-mechanical process control will be worked out and their potential for thermal and fluid-mechanical process control will be checked with the digital twin. These developed countermeasures will be tools which strengthen the options for real-time process control in the machine support system.

Advanced CC process control in real-time offering machine supported decisions

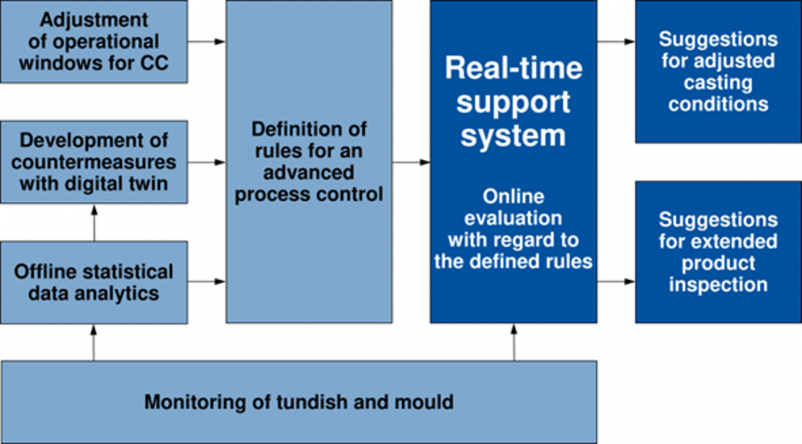

The chart below shows the organisation of the scheduled real-time support system with the different modules contributing to this system. Comprehensive temperature measurements in tundish and mould as well as the monitoring of the casting powder cover provide the basis for this approach. On the one hand, these data will be utilised for the offline statistical data analysis aiming at an assessment of the casting process and correlations with the corresponding product quality. On the other hand, measurements and monitoring will provide an online basis for the real-time support system. Here the defined rules for an advanced process control will be evaluated in real-time and the status of the casting machine will be judged, e.g. realised as a traffic light.

Organisation of the real-time support system

The project leading to this application has received funding from the Research Fund for Coal and Steel under grant agreement No. 847334. On 1./2. October 2019 was the kick-off meeting in the BFI. http://www.bfi.de/en/2019/10/16/kick-off-meeting-realtimecastsupport-october-1st-2nd-in-dusseldorf/

A workshop was held on Sep 08th, 2023 via Teams. The webinar presented key findings and discussed possible perspectives.

Please watch the video.

The 6 presentations of the RealTimeCastSupport workshop can be downloaded here.

1_RTCS_Webinar_Introduction

2_RTCS_Webinar_Measurement techniques BFI

3_RTCS_Webinar_Exploitation of various CC data

4_RTCS_Webinar_Digital Twin

5_RTCS_Webinar_Conclusions

6_RTCS_Webinar_Outlook

This project has received funding from the Research Fund for Coal and Steel under grant agreement No 847334.