Cyber-POS

Cyber-Physical Production Optimization Systems for Long Production Factories

Cyber-POS project abstract and objectives

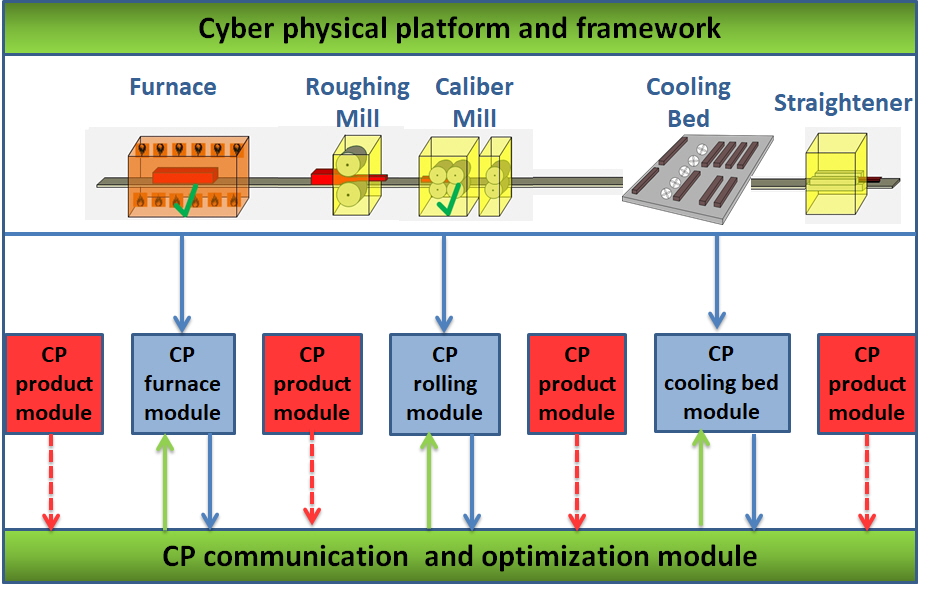

Production technology in steel industry has reached a level that significant improvements can only be reached by through process optimization strategies instead of improving each process step separately. Therefore the connection of suitable technological models to describe process and product behavior, methods to find solutions for typical multi-criterial decisions and a strong communication between involved plants becomes mandatory. Cyber-POS will develop a virtual simulation platform for the design of cyber-physical production optimization systems (CPPS) for long production facilities with special emphasis to thermal evolution and related material quality, leading to reduced energy consumption, shortened production time and improved product quality.

The main objectives within this project are:

- Optimization of throughput and reduction of energy consumption for the production of complex profiles in Mannstaedt’s hot processing line and

- Optimization of material quality and properties for rail mills at ArcelorMittal España.

This is achieved by applying the developed software and methods for the specific use cases. This implies the following sub-objectives:

- Virtual simulation platform for the design of cyber-physical production optimization systems (CPPS) for long production facilities; with special emphasis to thermal the evolution and related material quality, leading to reduced energy consumption, shortened production time and improved product quality;

- Merging of process models (thermal, rolling, transport), material-quality models, logistics/scheduling models and communication models (computers, software, networks);

- Strategies and methods for cooperative production optimization, enabling fast dynamic and flexible reaction on quality variations, critical states, measurement errors, and changes in set-points, production routes, process disturbances or interruptions;

- New and comprehensive, model-based (simulation) software for design of CPPS for long product factories, with a cyber-physical library for “drag-and-drop” implementation.

The project started at July 1st 2016 and ends at December 31th 2019. Involved partners in the research are:

| VDEH-Betriebsforschungsinsitut GmbH |

|

| Arcelor Mittal España |

|

| ASINCO GmbH |

|

| Fundación ITMA |

|

| Mannstaedt GmbH |

|

| Scuola Superiore Sant’Anna di Studi Universitari e di Perfezionamento |

|

Cyber-POS project expected industrial impacts

The research has received funding from the European Union’s Research fund for Coal and Steel (RFCS) under grant agreement No. 709669.

The main motivation for introducing the methods of cyber-physical production optimization is essentially to preserve the economic performance and safety level in spite of faults and process changes that may occur over time. The CPS platform to be developed can be regarded as an assistance system that will support plant personnel/operator decisions, and thus can contribute to the improvement of working conditions. All involved processes can actively communicate with each other, know their field of activity and production conditions. The optimizations made are also more tailored to the human workforce.

Higher maintainability, reliability and efficiency of long production factories through cyber-physical production optimization will lead to improved product quality, reduced maintenance costs and decreased material and energy consumption. This will have a positive impact on preservation of natural resources, energy and environment. Needless to say, reducing energy consumption leads to reduced CO2 emissions.

At the two involved plants of ArcelorMittal España and Mannstaedt, the developed concept will be installed as assistance system and tested in the process route reheating, hot rolling and cooling. This leads to increased flexibility of process chain, higher productivity, better disturbance management and energy savings.